Last night, I assembled my 4th QCX-mini, this one for 20m. On power-up it worked flawlessly; alignment was text-book, and the power output 4.6W at 12V supply rising to over 6W at 13.8V supply. On inspection prior to commencing the assembly, I found no cracked components, poorly soldered SMD etc. Everything looked perfect, as it did with the three previous kits I assembled (all from this first production batch).

After assembly this QCX-mini, I proceeded to undertake a detailed examination of 10 QCX-mini kit PCBs with a x40 Jeweller’s Loupe. In all 10 cases, the soldering was perfect and there were no cracked components, poor joints, or any evidence of hand-soldered rework.

This is a sample of 14. It does not guarantee that 100% of the production batch are fine. In any production batch, yield may be less than 100%.

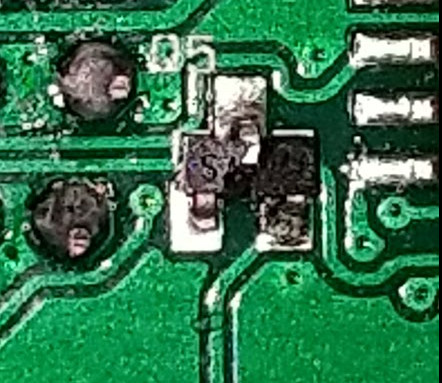

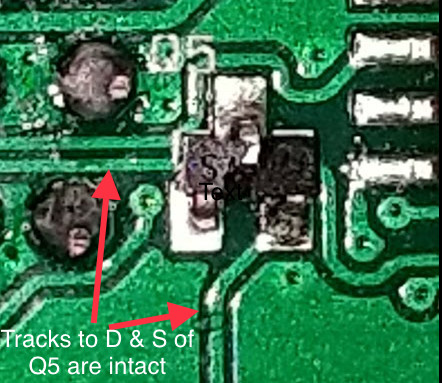

Regarding the cracked component in the photo shown, do not forget, that as in some other examples, this cracked component was found on an assembled board, during investigation of why the kit did not work. It is quite possible that some other assembly error caused the destruction of this component when the unit was powered. A physically cracked transistor is quite a common thing when they overheat. We just don’t know the circumstances leading to that cracked component. I’m just making the point that it may not be anything to do with a manufacturing error.

Of course I am also watching developments closely and always striving to improve the products and production, if there is any QC problem then we will find ways to improve this in future.

The assembly manual does clearly contain a paragraph, before commencing the assembly, suggesting a careful visual inspection before starting. I have also stated that in the event of any manufacturing defect, QRP Labs will of course consider it normal to provide a replacement board, just contact us.

SMD work is completely possible without any equipment. I have none here, either. It just takes good light, some optical assistance, with a good dose of care and patience. All of the prototypes were built with my regular 936D clone 60W iron with, believe it or not, a 3mm chisel bit. All it takes is patience and bravery.

Generally: if you damage (via assembly or operating error, etc) a small portable unit of such small size like this, then yes, if you need to replace anything, you would quite likely need to replace SMD components. This is the nature of the beast. It’s small, because it uses SMD. There is no difference here, to if we are talking about an Elecraft KX2 or KX3, FT817/8 etc. I intentionally kept the SMD components in the QCX-mini no smaller than 0603 and SOIC pitch ICs wherever possible, specifically to make it reasonably easy to undertake repairs if any turn out to be necessary.

For people who prefer something a bit larger, with all through-hole components, all kit assembled, the QCX+ has the same schematic, performance, firmware and features, in a larger format see QCX+ 5W CW transceiver kit .

73 Hans G0UPL, QCX-series designer