OK - it has now been through over 600 activations… and sometimes it has jammed and sometimes it has collapsed on its own. Every now and then small pieces of fibre material would fall out. But there was never really any reason to complain.

During my last activation of DM/BW-009, the mast could no longer be pushed together at the end. It got stuck in a middle element. I was then able to push it together to maybe a good metre and put it in the car.

At home, I put it in the corner and took a fresh mast. Call me neurotic - but I always have a spare mast that I take with me when I travel to do SOTA holiday.

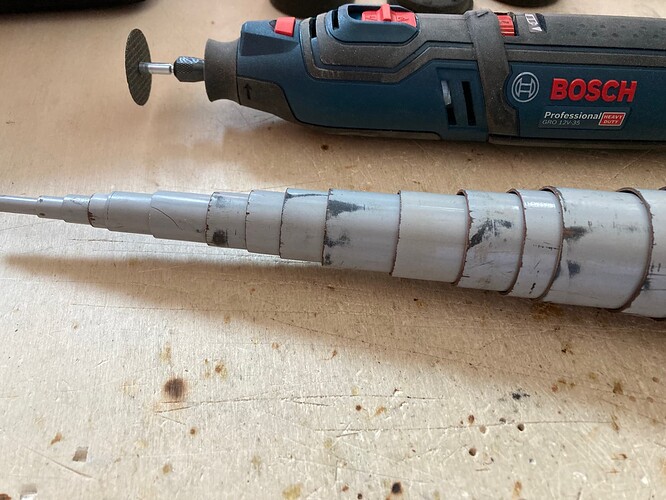

Today I took a closer look at my old mast. The problem was the frayed ends of the tubes. Here the laminate comes loose from the inside and then gets stuck and jammed. In some places I could see how it had already come off as a layer, but was still sticking.

Especially in winter, when these transitions get wet and freeze during activation, the layers separate.

The transition area where the sticking takes place is quite large… so now I just sawed off the sections where the laminate had already come loose.

gluing was not necessary at all, because there are no more loose spots.

Take a look at your masts… and if there is also fraying at the transitions, then you could perhaps counteract the tearing of the layers in this way.

73 Armin