…or into a river.

Hello Tim,

I like the 3D printed design, but I do have a suggestion on rigging the co-ax cable. My experience when using vertical polarization was that having the cable close and parallel to the driven element made the SWR variable and not what I wanted. I suggest running the cable back along the boom to behind the reflector, before allowing it to drop down.

Happy activating!

Ian

I have just purchased an FT65 as my FT1D seems to have developed an intermittent fault.

And so as you do, I have just created a couple of simple accessories ready for tomorrow’s activation.

First is a holder so I can keep my SRH770 vertical when using a hand microphone.

The second is related, a simple load spreader to take some of the strain off the SMA thread.

I’ve been looking in to 3D printers recently in a bid to start making my own antennas and radio mods. I’ve also got 2 Laserdisc players that I’d like to print spares for in future e.g. M Holders, cogs etc so would certainly look to break even on any printer investment fairly soonish.

What printer does everyone tend to use? I was looking at the Bambu A1 Mini without the AWS Lite as I don’t care for multicolour printing (for now).

Not looking to break the bank and keen for something quiet and with a small footprint. As for software I’d probably use something like TinkerCAD.

73

If you ez-mode 3D printing then get a Bambulabs.

EZ-Mode for sure. Wire winders, KX2 parts and mods, Quansheng mods, parts for a Yagi or Moxon of some sort etc.

If I can make something simple and give back to the community then that’s a bonus too. It’s hard to get stuff 3D printed for a decent price (not factoring in shipping etc and some stuff is not available pre-fabbed to the EU, at least not cheaply e.g. from the USA).

The A1 mini seems to be a good fit. Is there anything like it that might fold flat when not in use?

Ian,

I have a Bambu labs P1S, which I would recommend to anyone. Whilst not cheap, it is very easy to use, especially for people who don’t have experience in 3D printing. The slicing software is base on the Prusa Slicer, generally thought to be the best slicer. 3D printing has many stages (modelling > slicing > printing > finishing) and doing each one well yields results, but make a mistake in any step and it can fail. Having an enclosed printer makes a huge difference, especially when printing larger parts as it keeps the heat stable and stops shrikage due to uneven heating. I also have the AMS which, apart from swapping filament type (ABS / PET-G / PLA etc) and colours, it is also sealed with desiccant in the bottom to keep the filaments from absorbing moisture.

One of the points that can cause print fails or issues with print quality is leaving filament to absorb moisture from the atmosphere; as the filament passes the hot end any moisture boils off and can result in stringing or bubbles or blocked nozzles. The AMS helps keep the filament dry.

It’s also worth buying a filament dryer too. I have a drying oven, which I bought before filament dryers we really a thing, and can also be used to dry fruits and desiccant too for re-use, but there are purpose built filament dryers available for less.

Your other option would be to get a cheap Creality Ender 3 to learn and cut your teeth on before buying something more expensive

Personally, I’d buy once and buy well; it’s cheaper in the long run.

73’s

Dave.

My Ender 3 is still going strong after 4 (maybe 5) years now. Currently printing a bracket for my Lora tracker, before that a bracket to attach my broadband router to the wall!

I think you can get bed-levelling devices for the Ender 3 now? None existed when I had one, and was perpetually frustrated with bed levelling gremlins on mine. When it was level, it worked fine, but I had quite a few failed prints. It was a very early model and I think they’ve done alot of development with it. I killed mine by accident; the z-plane limit switch got disconnected by accident and I drove the hot-end into the bed and bent the frame, oops! ![]()

You could definitely get a BL Touch kit for the printer when I bought mine, although I didn’t buy it. It looks like there is an official kit from Creality now.

Seriously considering a 3D printer now - thanks for all the informative posts. I happened upon a pretty useful-looking calculator and ran a few speculative numbers in to it, just to see what it would cost to print all the projects I’d want to do initially and it appears to suggest buying a printer would be the better option financially, even for just running off bits and bobs.

Someone posted a 2m/70cm Moxon here a few days ago that I’d definitely want to build. In addition to a bunch of QMX and KX2 parts, wire winders and so on. Plus other things like A1 Mini mods e.g. Poop Bin. Also some parts for my Flipper Zero GPIO add-ons etc.

The Bambu A1 Mini seems to be the best fit for my needs. Anyone else have experience of this printer or anything by Bambu Labs? Are they any use? Decent warranty, customer service and so forth? Doubt I’d be going for the AWS add-on, I just want to print solid colour parts (for now). No space for the AWS anyway.

Here’s the calculator I found useful if anyone else is curious:

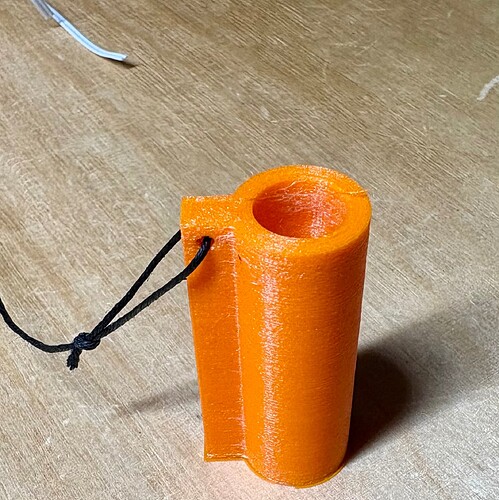

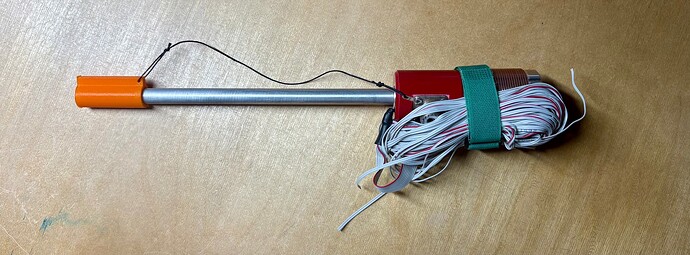

Antenne earth-spike protector

The spike on my Chinese (JPC12 or others) vertical antenna has repeatedly pierced the bottom of my backpack, so I designed a spike protector to prevent further damage.

It can easily be slid onto the spike after use in the field. To prevent losing it in the field, secure it to the antenna base with a thin cord.

You can download the files here: Antenne earth-spike protector by dl2sba - Thingiverse.

I’ve printed it in TPU – PETG and PLA should also work well – give it a try!

…great discussion everyone, I have learnt alot about this new hobby. Thanks.

Geoff vk3sq

And another thing to add to my 3D printing todo list. I read somewhere about a ground spike for a mast as well which could be handy.

When you print stuff like antenna parts etc, do you all use PLA or should you use PETG?

PLA is generally thought to be the most forgiving material to use, but PETG isn’t really any more difficult. If you get a Bambu machine and Bambu filament then it’s difficult to go wrong. All the Bambu machines self-calibrate meaning no bed leveling or other headaches. The Bambu filaments are all very stable and the material settings are done for you (provided you select the right material in the slicer - the AMS does this for you!).

Be aware that PLA degrades in UV, so if you are leaving a print exposed to sunlight all the time PLA isn’t probably the right material.

ABS is harder to work with, but mostly stable in UV. PETG is also stable in UV. I nearly always print in PETG. Its not much more expensive than PLA, but overall better in most aspects.

If you want seriously strong prints (engineering grade) you can get carbon-fiber filled PLA and PETG, but you will need an upgraded hotend (unless you go for a high-end machine which is already setup for using it).

If you get the A1 or any other open printer, consider buying a cheap enclosure for it, such as this one: link. It will make printing with PETG or ABS much more reliable. ABS also produces toxic fumes (although not all that dangerous - I’ve been around plenty of ABS printing and not died yet ![]() ) but it can also be an unpleasant smell. An enclosure like that makes printing with ABS more palatable/tolerable.

) but it can also be an unpleasant smell. An enclosure like that makes printing with ABS more palatable/tolerable.

Let us know what you end up buying!

Do you have experience with 3D modeling/CAD software?

73’s

Dave

G7SAT

I’ll use PETG if I need a stronger print. I use PLA for everyday items.

This is one of my first prints with TPU, a flexible yet strong material. I’m pretty impressed with its performance. I followed the filament parameters recommended by the manufacturer and it worked flawlessly.

I’m using an old and cheap Anycubic I3.

Great stuff! I’ll probably go the PLA road for now so. KISS and all that. I just want to download a model, print, make a cup of tea, come back, job done.

The A1 Mini looks to be ‘the one’. Gonna stew on it a bit, do some more sums (and think where to actually put the thing in a small home office!) and go from there.

Last time I ever used a 3D program was probably a demo of 3DSMAX and Amos that a friend had on a copy of Amiga Format. ![]()

TinkerCAD for me I think!

You can get a long way with TinkerCAD.

That’s a fantastic starter printer. Bambu Labs have really changed the printing landscape! Great kit

It handles PETG really well and this is an ideal material for portable SOTA parts.

It looks the bizzo and its on sale at the minute. Does anyone know if you need all those different hardened steel nozzle sizes? Or just use what it ships with?

So many accessories to buy at heavy discount in the sale that its overwhelming for a newcomer.