It’s why you join a radio club… to meet people with other skills you can learn from and who will help you.

Something like this is probably what you need. Check the exact size you need.

It’s why you join a radio club… to meet people with other skills you can learn from and who will help you.

Something like this is probably what you need. Check the exact size you need.

I have a box of those. This morning, I performed some measurements, and here is a comparison between them, and an authentic mix 31 clamp from Fair-Rite:

| Attenuation at 14 MHz (dB) | |||

|---|---|---|---|

| Turns | Fair rite #31 M10 | Random ferrite M9 | Random ferrite M7 |

| 1 | -4,6 | -2,4 | -2,55 |

| 2 | -12 | -7,6 | -7,44 |

| 3 | -18,3 | -12,1 | -10,85 |

| 4 | -24,5 | -17 | N/A |

If the ferrite choke is already on the coaxial feeder, then the problem is partially solved. The HF current on the outer surface of the cable shield is already significantly weakened. Accordingly, this HF current will not be present on the radio body and headset wires. But the field from the antenna does not go anywhere when working on transmission. Accordingly, common-mode currents induced by this field can get into the transceiver circuit through the power wires and accessory wires. Of all the methods for combating HF interference and common-mode currents, one is often enough. But there are very unfortunate coincidences of antenna parameters, feeder configuration and ground parameters under the antenna. And then the HF current can "bite fingers on the CW key, cause interference in the microphone, and even sometimes disable the radio itself. In this case, a full set is appropriate.

73

Vlad

I would recommend putting a ferrite choke on the external speaker line to protect the audio power amp IC (that chip Vlad replaced). That is in addition to the choke in the feedline (which is highly advisable to have regardless of the radio’s idiosyncrasy).

The reason is, the RF current can be generated in the external speaker cord by the electromagnetic field generated by the antenna. Having a feedline choke can reduce the common mode current but if the interference comes from the radiated power that choke has no effect. Only the choke on the speaker line can reduce that RF current. Of course, the same fix can be done with much less weight and cost (like 0.02 grams and USD 0.5) if implemented on the board.

There is no direct evidence that was the direct cause of the TDA7056AT failure, but the circumstance suggests that is the most likely mechanism I can think of.

It’s probably not a bad idea to have ferrite choke on the key line, because those lines go to more sensitive circuits than the audio power amp outputs. It’s also ok to use 220 or 330 ohm resistors (much smaller and lighter) instead of chokes for this line, as long as the keying functions normally.

Ferrite choke on power line is probably less important, as I don’t really see failure reports that make me suspect that area. But when you use a lithium battery pack with BMS, etc. those BMS board can malfunction into protection mode (power cutoff) or fry the chips, so I have 31 core choke on the DC line for my 100W station setups (both my bicycle station and SUV station).

Now responding to other posts:

The efficacy of the ferrite materials used for chokes are measured by the complex impedance Z = R + jX with one turn coil. “Attenuation” is not the right measure. For feedline choke, you want R > 1000 (you want the R component to be very high on all bands used, not just X). For the speaker line protection, R > 200 is probably adequate. A medium sized 31 or 43 cores with 2 or 3 turns should easily meet that. 43 ferrite also works but probably require a bigger core and/or one or two extra turns. (Single turn on snap-on cores are not really effective for HF uses. You’d need many many cores to meet the target. But 3-4 turns make it much better. Details vary on the core size and shape.)

I spent a lot of time doing analog/RF stuff so I know in those areas but I’m new to outdoor activities including mountain day hiking. I did hike mountains for school trips, etc. when I was a kid but that’s about it. I’m learning things in a different orders but it’s always been a learning process.

Thank you, it’s very interesting. I’m going to repeat the experiment, then. Now that you mention it, I remember the famous chart by G3TXQ about chokes, and it’s indeed the R values that are presented. He considers the choke to be very effective when R > 8k. Protocol also described by Owen D.

Most articles and videos, however, recommend measuring the attenuation in dB. I guess I need to read a bit more on this topic.

Just as an idea, this is a closeup of the choke portion of the feedline I use in SOTA activations.

Each core weigh 10g, so I have 30 grams for those cores.

For TX-500 speaker line, I would probably use a smaller core but wind more turns.

Of course, R > 8k ohm would be fantastic, but in my opinion, it’s also an excessively high requirement. We have a limitation of being a portable operation (operating position is very near the antenna) and also QRP. For my 100W setup, my chokes are R > 2000 and |Z| even higher.

These high impedance is needed not only to block the common mode current in all sorts of unexpected current/field distribution conditions that can actually happen (maybe not right when you are testing the setup), but also to minimize the loss and heat generated by the cores. Better design and implementation allows more weight-efficient solution.

I also learned a lot from Owen Duffy’s website and routinely use some of his online calculators. One of very few no BS amateur radio RF resources.

Paul and others, I think the problem is probably 85+% preventable by blocking RF common mode current into the speaker port, but if this helps at all, I thought to share this story with you. I have an SMD work setup on my bench (microscope, iron, hot air gun, etc.) so I never thought about anything like this.

My friend, who is not a ham and not a very electronics-savvy guy recently got interested in SDRs and wanted to change the chip on a preamp PCB assembly he bought from AliExpress or somewhere, with a higher grade (better NF, etc.) one. He bought the chip from Digikey or Mouser or something, and organized all the modification info from online sources. Then he stopped by local independent (not authorized) cellular phone repair shops and chatted with the young tech kids and looked at how they worked at the bench. When he found one that looked competent and had serious interest in electronics hobby in his personal time, he came back with the board, the chip, the information resource and offered to pay some reasonable money to have the chip swapped. I don’t know how much cheesecake or apple pie or whatever he brought to the kids to get that conversation going, but some of those might help.

So, if anyone unfortunately have a complete loss of audio output, and suspect TDA7056AT failure, but authorized or unofficial repair service is not available at all, the same technique could be possibly used. Vlad’s documentation on this thread will be all they need to do the job. Just remember to double check which package TDA7056 you are buying. (From Vlad’s picture I presume that is TDA7056AT.)

TDA 7056AT/N2 by NXP Semiconductor

73

Vlad

Perfect. With a minor editing this thread can be made into a service bulletin. The manufacturer should hire us haha.

Lots of interesting stuff in this thread!

I have been using this rig for over 3 years now, which corresponds to almost 400 activations on three continents in different climatic conditions. I have also used it unprotected for extended periods in pouring rain and sleeting snow. When I opened the case once to check for debris (I didn’t find any), I, like @RX9WT, expected to find some sort of rubber seal around the case. I would describe it as water resistant, but not waterproof.

Fortunately I never had a failure, but I did experience some RF audio feedback on the 17m band and above when using my EFHW next to the TRX. My solution was to connect a CMC to the BNC antenna socket of the TRX, as I explained in another thread, where I linked to the QRP CMC, which seems to be available again. Other than that, I don’t use any other RF protection.

This rig is not perfect, but I like it for its robustness and ease of use. As I have only used it on SSB, the 48kHz wide spectroscope suits me perfectly, but I agree that this is definitely too wide for CW.

I was never interested in the BP-500 battery pack, and in IMHO it was wrongly designed for several reasons.

Back to the main topic about the TDA7056AT: On groups.io I read about several others that fried this (outdated) audio amplifier chip and it seemed that it also happened when only the speaker mic was used, but always after TX. Probably only Lab599 knows the exact cause…

73 Stephan

Interested final point there, I’ve rarely used the hand mic.

That point is entirely consistent with my analysis that the RF current coming from the external speaker wire (hand mic cord) killed TDA7056AT. More reason to put ferrite chokes (a few turns, not just a single turn) on that line.

Feedline common mode choke is highly advisable but that itself is not a protection for this particular problem. Maybe a partial protection? That answer depends on how everything is arranged, the ground terraine, etc. and I certainly would not want to gamble on it.

An interesting point is that you don’t have to use the same feedline through the cores.

You can use a tiny teflon coax - even the tiniest has high power ratings.

You can just use a twisted pair.

This makes it much easier to get (say) 8 turns on a small core.

Because the choke function is to stop rf current, when you have plenty of turns, the rf current is small, and a small core is just fine.

Also as Ryuji says, multiple turns are needed. L~N^2. A single pass through one core has very little (close to nil) effect on lower HF. It is this way in computer equipment because the frequencies they are usually having trouble complying with are UHF and VHF, and they are often just trying to get a few more dB to put them under a spec line.

Silicon grease, as used on spark plug cables (not sealant, and not heatsink paste) applied to the joint can prevent water wicking though due to its repellency. It won’t stop pressure forcing water in, but it can stop droplets from being sucked through a capillary gap by surface tension.

That would work. However, in/near delicate mechanical work, the grease may creep and make some moving parts stick, so be careful.

In the antenna world, Gardner Bender Ox-Gard Anti-Oxidant Compound is a very common grease with antioxidant particles mixed in. It is commonly used in antenna deployment. It enhances electrical contacts (the grease itself is not conductive at all), prevents water getting in, prevents corrosion, and facilitates removing the joint, even years later. Very useful in connectors, pipe joints, etc.

Yesterday, for the first time during an activation, someone said I had distorted (TX) audio.

I also noticed some humming in my headset when transmitting. The humming disappeared after clamping a ferrite on the headset cable, but the distorted TX audio didn’t, according to reports.

It’s unbelievable that this happened the day after I participated in this forum thread.

Anyway, because I was using a new headset and a new coax cable for the first time, I wasn’t sure what was causing the problem.

Back at home, I plugged the radio into my shack antenna and recorded my voice via a distant webSDR, and everything sounded perfectly fine. So my suspicion shifted to my EFHW antenna and common-mode currents. Since my coax cable isn’t exactly the same length as before, the common-mode currents might have been higher. This really convinced me to build a proper choke. According to simulations (found here), placing the choke 1.8m from the transformer gives the best results (for a 20m long antenna).

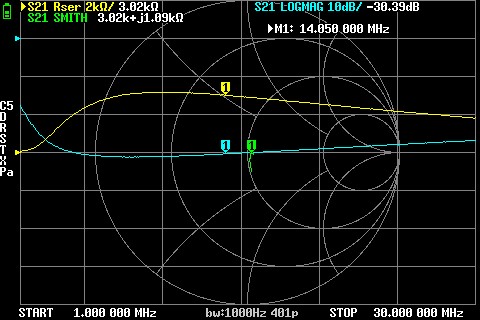

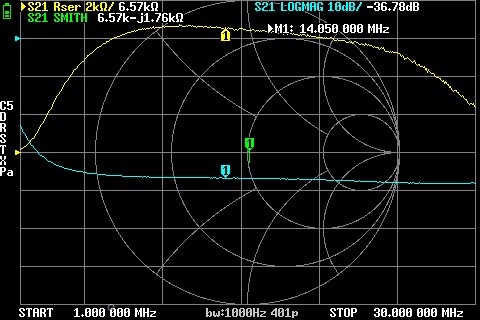

I built one on a FT114-43 core, bifilar, 15 turns each side.

And one with two FT114-43 cores in series, bifilar, 14 turns each side.

The next step will be to fit it in a case and test it with the real antenna.

The goal was to build a choke with >3k ohms (I got nervous about frying the radio, haha).

I already had a few FT114-43 cores and some type 31 clamps and cable cores.

After a few attempts with the #31 cores, I couldn’t get more than 2.7k ohms due to the low number of turns possible.

Then I started experimenting with the FT114-43 cores and built what you saw.

About wiring, it’s a mix between sectional and bifilar winding, looks like a guanella but it’s not. At least from what I know (i.e, not so much).

Edit : You deleted your post so I will also stop my digression here to avoid deviating from the original topic ![]() .

.

To prevent frying the AF amp chip, you don’t need a very high impedance, but it also needs to be on the speaker line. The speaker wire interacts with the RF field generated by the antenna itself (not common mode current) and generates RF current, which goes directly into the amplifier output pins and flows into the chassis ground through the amplifier chip. That RF current kills the chip.

Of course the role can be reversed: the speaker wire can have the near-ground potential, and the common mode current from the coax injects the RF current through the same path as above.

But the reality is most likely a combination of the two. Best to have choke on both.

Note that the choke’s RF resistance of 200 or 500 ohm on the speaker line is probably enough to prevent the chip from blowing. If you want to make a custom headset adapter cable yourself, you could insert small RFCs instead of winding coax to save bulk and weight, as well. This is a lighter requirement than the choke on the feedline.

Now feedline choke of choke resistance above 3000 is fantastic, but it is an overkill for a 20W station or less, especially when the bulk and weight are of concern. Some people aim 3000 or 8000 because they want to operte 1.5 kW. If the choke resistance is not high enough and pump in QRO power, the core will heat up and deteriorate. If anything other than teflon wires are used, the insulator will also melt and the windings will short inside. (Ask how I know…)

P.S. I deleted it because I remembered about bisectional windings of two Guanella transformers on a single core… and I mean to look up my notes and references, but if you have more explanations to tell, I’ll be happy to read.

Yes, I will totally follow your advice and loop a few turns of the audio cable in a #31 clamp-on ferrite. I already crafted my own headset for the TX-500 (which I used for the first time during yesterday’s activation), and I felt like my equipment and skills were being pushed to their limits with those tiny enameled audio wires. Inserting micro components on such lines is challenging… I’m not sure for now. ![]()

One extra FT114-43 is only +14g; I think I can afford it, even though I see what you mean.

Oh I might have lost my sense of component weights. I just went to my bench and weighed. FT114-61 is only 12.2g, FT140-61 is 31.1g. (I’m out of 43 in those sizes… I prefer more tubular shaped cores for feedline transformers and chokes now, because they give wider bandwidths.)

Now I think about even lighter choke that is still effective… (Outdoor people get obsessed with titanium but we get ferrites ha)