Selection bias Brian. ![]()

True, but if its at the top of the fishing pole it is, I saw an article in SPRAT this month where the “designer” had used a 259 on the balun box at the top. I learn’t that lesson a few poles ago !

I have seen a few home-brewers use RCA phono plugs before with good results up to 30MHz. Simple plug and socket combination.

Jonathan

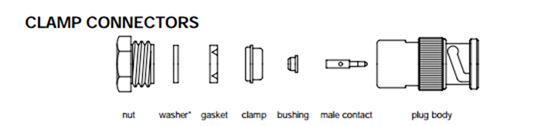

Well, there are such things:

I have used them in a former life with IBM network controllers. They only work with solid centre conductors, as the centre also “screws on”. Very quick to fit, but I don’t like solid centre coax where it is frequently moved around.

One difference I can think of between BNC and PL259 is that in the latter the centre conductor is soldered at the tip of the plug, which means that there is some protection afforded by the “tube” it passes through, and a greater length before the cable grip, which provides some flexibility. Whereas in a BNC, the connection is more rigid right close to the cable grip, which gives no protection against differential movement of inner and outer. If that makes sense ![]()

Anyway, thank you all for the comments, I’ll ponder…

Adrian

G4AZS

Maybe, but I used a pulsed ultrasonic tester on concrete in the lab and on site for over thirty years and the BNC patch leads between the “PUNDIT” and the leads failed on a regular basis. I think they are OK in the shack where they will be left alone for long periods but they are not suitable for use in the field where the leads will be repeatedly coiled and uncoiled and the plugs repeatedly installed on and taken off the sockets - and I am talking about commercial leads with thick rubber protection over the plug and end of the cable, not flimsier home-brews with a bit of tape or thin heat shrink to protect the join. They are just not man enough for the job.

Brian

Thanks Adrian, I have seen them before but not on a cable

I’ll give it ago sometime. RG174* is the medium here though.

Jonathan

It’s good that you found and solved the problem Adrian.

I also subscribe Jonathan’s counter rotation of the inner pin against the coax itself theory.

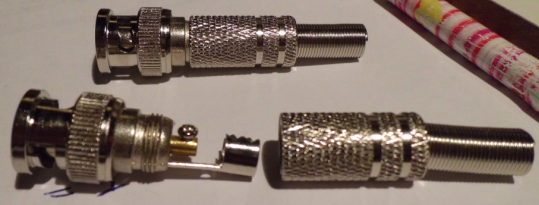

This type of BNC connectors I recently bought in Pamplona might be easier to connect, diagnose in case of fault and repair than the crimped ones you used.

However, I use a total of 5 PL-259 in my SOTA kit:

the one connected to the back of my FT-817,

the one connected to the transmitter SO-239 connector of my MFJ Antenna Tuner,

the one connected to the antenna SO.239 connector of my MFJ AT

These 3 are never moved nor disconnected as they are inside the wooden box containing the preconnected rigs.

See:

One short length of RG58 comes out of the box with another PL-259 permanently connected to a “barrel” SO-239+SO.239 adaptor and covered with insulating tape. You can see it on the top left picture of my 23/05/2015 post.

All I have to do when activating SOTA is connecting one single PL-259 from the antenna I’m using that day to the barrel adaptor.

The only PL-259 I use to connect and disconnect to the barrel has needed repair in both cases, the one I use with the mobile whip antennaes (on a RG213 cable) and the other one I use with the 7m long GP (on a RG58 cable).

Best 73 de Guru

I’ve 400+ activations using BNC with one cable failure (intermittent break RG174) and one BNC failure after tripping on the cable. If you were having regular failures on BNC connectors and I’m not then I’d be looking for what else was common to your setup when you were having failures.

Yes, That’s all I use on my portable equipment. Simple, reliable and light.

All my other gear is BNC. The only 259 socket in my entire collection is the one on the back of my FT7. That has a 259-BNC adaptor.

I’d say the issue with Adrian’s failure was a nicked inner core whilst stripping. I’ve seen it hundreds of times in installations that I’ve had to commission.

72

I’m with Jonathan on this one, SO239/PL259 are just a tad bulky.

My FT817 is fine, I’ve never had a problem with the connectors but I have repaired a friend’s FT817 where the central pin on the SO239 had been broken off the PCB. An easy fix but there’s very little mechanical support of the centre conductor. I’m always super careful when plugging cables into the back of my FT817! I think that a bit of rough handling or some sloppy soldering on the PL259 pin could soon cause connector failure.

I’ve had one BNC fail, the coax (RG-174) had been rotating about the middle pin causing an open circuit. The BNC was replaced FOC by the manufacturer. On the whole I think BNCs are fine for SOTA, it’s certainly the connector that I have standardised on.

Two of my MTRs use RCA/Phono connectors, I know it’s common for people to replace these with BNC but I like to keep things as the designer intended. I believe that quite a bit of thought went in to using RCAs on the ATS series rigs. For one thing, if you’re out hiking for a number of days and need to pick up a new antenna connector for whatever reason, you’re more likely to source a phono (RCA) plug than an RF connector. Also an RCA jack weighs quite a bit less than a BNC so reduces the rig weight and will have less leverage on the case (a bigger issue if using Altoids tin). Some people reckon that RCAs disconnect too easily but I have not had a problem. The losses / mismatch etc is also really not an issue - I managed some >3000miles QSOs on Sunday through RCAs adapted to BNC on RG-174 with about 2w out from the rig. My usual MTR antenna has an RCA plug straight on to the RG-174. I like the price of RCA connectors

I was also laughing to myself reading that piece in SPRAT, that device looks so heavy!

- Colin

Well… Mountain Topper Radio uses RCA and that works fine. ![]()

Also Heathkit QRP’s rigs used to use it in the 80 and 90’s (HW-7, 8 and 9).

I use RG-174 plus Amphenol BNC’s and it seems to work FB. The only issue that I ever had is a broken center conductor (coax cable).

This one uses a sleeve and a PVC sleeve from Sotabeams

I don’t use PL-259 any more and my SOTA kit is a all-BNC one. The only exception is the KX-3’s 2m transverter which uses a SMA…

73 Pedro

I’m 100% BNC and N type on all my gear!

N at home for powerful stuff, BNC (Crimp or Pressure Sleeve) for SOTA and lightweight things at home.

I do not use the front BNC on the 817 as I wish to preserve it, so instead stick a high quality adaptor on the back of the rig to get from PL259/SO239 to BNC Female.

We have had these debates before, everyone has a different view on this. I suppose it all boils down to what you’re happy with. If i could be bothered, I would change all my BNC to TNC, however that is alot of patch cables that need modding.

Adrian, I am glad you cracked it, last time I had issues, I thought it was the connector, I opened up the plug and found the plug was fine, it was the water and blackened copper that had caused me the issues!!

73

Matt G8XYJ

Heathkit’s HF 100 watt radios also used to come with RCA sockets as standard. They were used for interconnections on Collins equipment too.

Although they are considered an audio connector, RCA sockets were apparently originally intended as microwave connectors and if the right series of plugs and sockets are used for the cable, their impedance characteristics are good. The modern type using a kind of mud as the insulator would not qualify though. The ones on radios mentioned above had ceramic insulation.

I use BNC for everything - I would replace the SO239 on the back of my rigs with a BNC if it was easy. As it is, there is a BNC adaptor almost permanently installed. It is only removed when I use a tuner for HF or an amplifier for a vhf band.

@G4AZS

Perhaps you have scratched the wires of the center braid when removing the dielectric as mentioned by G2HFR. Such scratches can cause the wires to break later. (Same mechanism as cutting glass: Create defects inducing a break.)

I use a snap-off blade utility knive to carefully cut the dielectric without hurting the center braid.

I have a BNC male - BNC female right angle adapter permantly attached to the front BNC socket. This not only protects the front socket of the FT-817 but also the coax is less disturbing when using the set dial below the socket.

73 de Michael, DB7MM

Hmmm, and to think that I started with RG-213 and N type connectors… well, I do use 2m and 70cm. I thought you HF types used wet string anyway - no need to carry the water to wet the string on most GM summits. ![]()

My preferred cable is now 5D-FB with its special size BNC connectors (solder type). Being low loss semi-rigid I find it much easier to roll up in sub-zero temperatures. If there is any cursing to be done on a summit it is usually on account of the RG-58 HF dipole feeder. I appreciate many prefer crimped connectors, but I have had no issues with the soldered BNCs on either feeder. Mind you I do keep a check on them after every round of activations…the 6P principle and all that.

Agree entirely with this. The cable can get in the way when trying to make adjustments to the controls, particularly with numb fingers in cold conditions…

73, Gerald G4OIG

Hi Adrian

I’ve used crimped BNC’s for a good few years now on my SOTA kit (and the shack based stuff) and not had any failures, even on repeatedly-used patch leads. I have occasionally found when assembled the central pin has come up a bit short - presumably due to “operator error” on my part - which perhaps would give the pin more wiggle room and thus increase the chances of fatigue of the inner conductor at the interface between it and the crimp on the pin, but I’ve weeded these out before they’ve gone into service.

I use a heavy duty rubber boot rather than heat shrink, and put a small cable tie at the cable entry end to hold in place. Also a stripping tool set to the correct dims for preparing the cable, so no risk of nicking. The combination fortunately seems to give me excellent reliability (he said just knowing the next activation will be the one when the BNC falls off…)

73 de Paul G4MD

Thanks everyone for your thoughts, interesting and helpful.

Closer scrutiny of the broken wire shows that it broke right up against the crimp, and not right next to the end of the insulation where “nicking” would be most likely. There is maybe 0.5mm difference, as the crimp grips the wire just inside the “tube” of the centre pin, and not right at the open end.

I guess that the BNC was optimised as a constant impedance connector, and any robust cable grip would risk compressing the cable, causing a blip. So, it may not be ideal for SOTA type field work, although obviously it works well for many of you here.

I like the idea of a BNC right angle adaptor, and will be acquiring one at the next opportunity.

I don’t really want to use the rear connector, as I often operate with ft817 standing on end. I have fitted a cover over the SO239 to protect it.

Anyway, I’ve just fitted a new connector to the antenna coax, taking great care to avoid damaging the wire. This time, I have made the centre pin crimp closer to the tiny inspection hole, and therefore away from the open end. I hope this will mean that the pinch point of the crimp, where fracture seems most likely, will be protected a little from strain.

I’ll also rethink what to carry with me as backup, though in this case it didn’t cause me too much of a problem.

Best 73, and thanks again for all comments,

Adrian

Hi Adrian,

I wonder if there are right-angle connectors (plugs) rather than adding an adapter to a straight plug. I know there are for PL-259s so hopefully they exist also for BNC, that way it’s one less component to go wrong - get left behind, etc.

Ed.

[quote=“DD5LP, post:24, topic:12375”]hopefully they exist also for BNC[/quote]Yes, they exist, but you may have to go somewhere like Farnell or RS to find them.

I suggest the crimp is fine and I agree with others that the failure has resulted from the plug wagging about whilst the cable is moved. The resulting articulation will be applied to the point on the inner between the pin and the insulation. This is the common mode of failure for ALL BNC plugs. I have also experience of socket damage caused by the pin wagging within the socket. The direct solution is to use TNC’s (threaded N connector) for this type of application. These are direct peplacements for BNC’s but they are more difficult to source. They are the solution for wagging cables. Being screwed together a mechanical solution is achieved, the pin is unable to articulate the plug lasts for ever.

David G0EVV

The jury must still be out on that one surely?

![]()